Boost Factory Productivity and Safety with Thermal Imaging Solutions

Waste heat generation and hotspots are inevitable in any manufacturing process

Boost Factory Productivity and Safety with Thermal Imaging Solutions

Waste heat generation and hotspots are inevitable in any manufacturing process

Extreme temperatures can adversely affect equipment lifecycles and also pose a serious threat to worker health. Monitoring overheating, underheating, hot spots, and undesirable temperature-associated conditions can reduce the likelihood of unplanned downtime due to equipment failure, reduce breakdown maintenance costs, and extend the lifespan of equipment. Thermal imaging cameras can avert potential problems by monitoring the temperature of critical equipment in real time. These cameras can detect hot and cold spots. This article covers the benefits of thermal imaging to boost production and ensure industrial safety, some practical examples, and factors to consider when selecting a thermal imaging system for different industries.

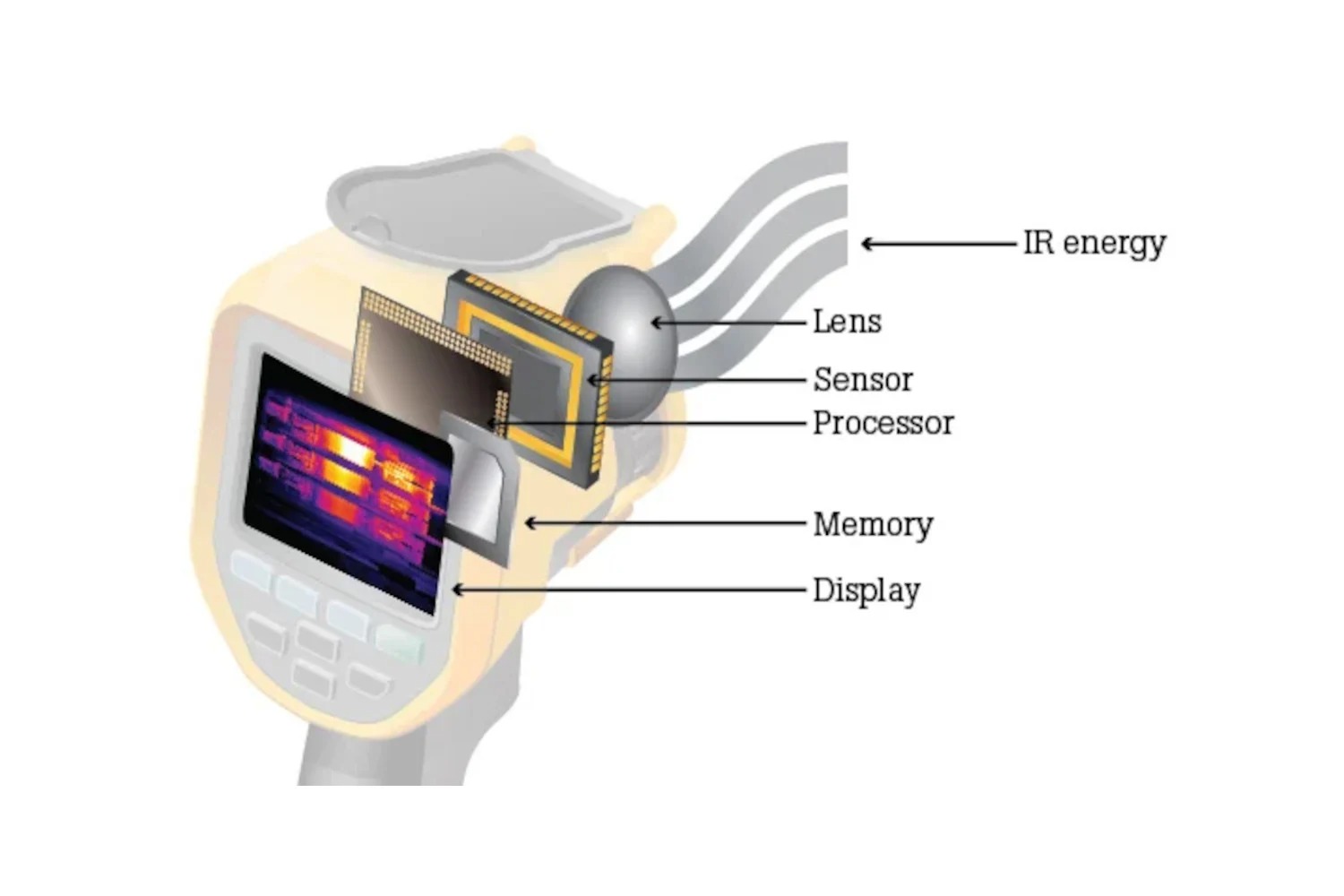

A thermal imaging camera works on the fact that there is an emission of some amount of infrared radiation (IR) from every object above absolute zero temperature. Although human eyes have limitations in perceiving IR light, the camera detects and measures the IR energy emitted by objects. This information is subsequently transformed into a thermal image (also called a thermogram). The thermogram represents the surface temperature of the object.

A thermal imaging camera uses an optical system to capture and focus the IR energy onto a detector chip known as a sensor array, which contains thousands of pixels arranged in a grid. Each pixel responds to the IR energy by generating an electronic signal. A mathematical operation is then performed on these signals by a processor of the camera, which creates an equivalent color-coded map based on the temperature of the object. Each color corresponds to a specific temperature, and the final image, or thermal map, is stored in memory and displayed, showing the temperature distribution of the object.

Figure 1: Working of a thermal imaging camera (Source)

Thermal imaging cameras help detect unfavorable conditions so that appropriate actions can be taken in advance. Following are some key benefits of thermal imaging cameras and their readings that help optimize and improve maintenance practices across various industries:

Thermal cameras are used in various applications across various industrial and domestic applications. The following are some common applications of thermal cameras in various industries:

The selection of the right thermal imaging camera entirely depends on the industry-specific requirements of the particular process application. Following are the factors to be considered:

Temperature resolution: The higher the resolution of a thermal imaging camera, the smallest the change in temperature it can detect. Also, a thermal camera with higher resolution provides clearer and more detailed images that makes it suitable for applications requiring a high level of accuracy. Resolution or sensitivity for IR cameras is commonly expressed as Noise Equivalent Delta Temperature (NEDT). This figure of merit tells about how much a thermal imaging camera can detect the smallest temperature change above its noise floor.

Exposure time: It tells how quickly a thermal imaging camera can capture a single data frame. It is similar to the shutter speed of a normal light camera. It is also called the integration time or thermal time constant of a detector. These terms simply tell the amount of time taken by a thermal imaging camera to capture a single thermal image.

Frame rate or Frames per second (fps): This describes the number of thermal images collected per second from a thermal imaging camera. A high frame rate is helpful in capturing the thermal signature of fast-moving objects. The camera can then capture a frame and play back in slow motion.

Field of view (FOV): It defines the area a thermal imaging camera can capture within a specified time. A lens with a wide FOV (45° or higher) is beneficial for scanning larger areas, while a telephoto lens with a narrow FOV (12° or 6°) is better for focusing on smaller, more specific areas. A few cameras are available with multiple lenses for different applications.

Functionality: It includes additional valuable features present in the camera, such as video recording and the ability to capture or connect to other devices for data sharing. Modern thermal imaging cameras come with a variety of features, such as Bluetooth connectivity, normal camera mode, WiFi connectivity, and other ergonomic features.

Hazardous environments: Inspection of process equipment in industries surrounded by hazardous environments is a challenging task. Inspectors and condition monitoring experts who monitor industrial facilities like natural gas burning sites or gas liquefaction plants require a hot work permit to be obtained in advance and signed off by multiple line managers. This practice is praiseworthy, but obtaining a hot-work permit can take up to several hours and may be valid only for one shift in some cases. Also, in cases where there is some unexpected delay in the site or due to the unavailability of the workforce, the maintenance or site inspection process may remain pending, potentially worsening, since these permits are valid for a limited time and need to be renewed after their validity expires.

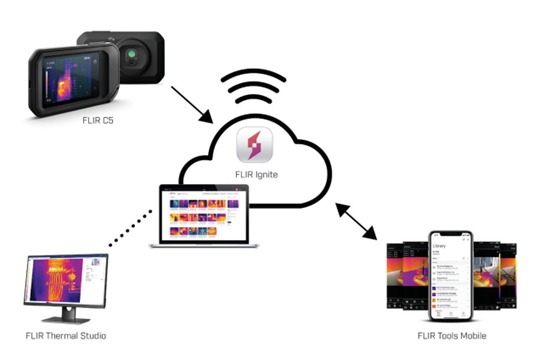

The above challenges can be mitigated through FLIR C5, a hazardous environment compatible thermal camera from Teledyne FLIR. This device eliminates the need for time-consuming hot work permits and unnecessary paperwork. FLIR C5 is a compact camera that features an FLIR Lepton® thermal imaging sensor and FLIR-patented MSX® (Multi-Spectral Dynamic Imaging) technology. This technology helps in the transformation of real-time temperature of the site under inspection into precise thermal images. Another remarkable feature of FLIR C5 is the FLIR Ignite cloud-based solution. This helps professionals directly upload, store, and back up images captured by the camera on the cloud, share data with team members, and create diagnostic reports. FLIR C5 is a pocket-size thermal imaging solution that helps maintenance professionals quickly identify and diagnose hidden problems.

Figure 2: FLIR C5 thermal imaging camera with cloud integration feature

With 384 x 288 infrared resolution, an IFOV (Instantaneous Field of View) of 1.91 mRad, and precise manual focusing, the TiS75+ simplifies preventive maintenance. It provides an advanced level of efficiency and accuracy in thermal inspections. The TiS75+ captures standard and radiometric video, monitors high-temperature processes up to +550 °C, and records standard and radiometric video of up to 5 minutes in length. It also offers IR-Fusion® AutoBlend™ and picture-in-picture (PIP) to blend a visible light image with an IR image of the same target at five different levels to locate problems more easily. Ti75+ has user-selectable hot and cold points and internal/external range color alarms. It also modifies the palettization of an IR image by limiting which pixels are drawn using palette colors based on pixel temperature.

The most interesting feature of TiS75+ is that it allows sharing images in real time across teams using the Fluke Connect app. This feature allows creating and emailing reports from the job site and saves a lot of time.

This article helps in making informed decisions while selecting a thermal imaging camera for predictive or preventive maintenance. Farnell offers a wide variety of thermal imaging cameras and associated accessories that contribute to achieving the operational efficiency of your manufacturing plant. They also safeguard valuable assets and manpower from catastrophic situations and, naturally, the associated costs.