BMS and ESS explained: Powering the future of commercial transport

The commercial transport, including buses, trucks, and logistics fleets, is switching to electric power to meet strict emissions regulations and sustainability goals.

BMS and ESS explained: Powering the future of commercial transport

The commercial transport, including buses, trucks, and logistics fleets, is switching to electric power to meet strict emissions regulations and sustainability goals.

The International Energy Agency (IEA) reports that worldwide demand for electric vehicle (EV) batteries topped 750 GWh in 2023, with commercial vehicles being a significant factor. Battery Management Systems (BMS) and Energy Storage Systems (ESS) are key to this shift, helping electric commercial vehicles perform well, safely, and reliably. This article explores the technical details of BMS and ESS, how they are used in commercial transport, and recent innovations, technical advancements, and applications.

A Battery Management System (BMS) is an electronic control circuit designed to monitor and regulate the charging and discharging of batteries. It manages rechargeable battery packs by tracking various battery characteristics, such as battery type, voltage, temperature, capacity, state of charge, power consumption, remaining operating time, and charging cycles. BMSs play a crucial role in commercial transportation by ensuring the safe and efficient operation of rechargeable battery packs. Its core functions include:

ESS is the larger infrastructure that integrates battery modules, BMS, power conversion systems, and thermal management units into a cohesive platform for storing and delivering electrical energy. In commercial transport, ESS refers to the battery packs that store electrical energy to power electric vehicles. Predominantly, these are lithium-ion batteries due to their high energy density (100–265 Wh/kg), efficiency, and declining costs. The two primary chemistries are:

Emerging sodium-ion batteries, with energy densities of 140–160 Wh/kg and lower costs, are also gaining traction for smaller commercial applications. ESS in commercial vehicles typically ranges from 300 kWh for buses to over 850 kWh for long-haul trucks, requiring robust integration with vehicle powertrains.

Electrifying commercial fleets—ranging from delivery vans to Class 8 trucks (the heaviest-duty commercial vehicles, defined by a Gross Vehicle Weight Rating [GVWR] exceeding 33,000 lbs)—requires high-performance ESS and intelligent BMS for several key reasons:

Figure 1: Powering fleets with BMS and ESS

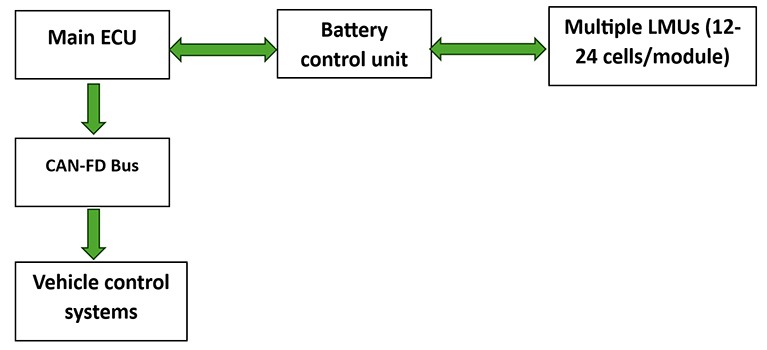

BMS in EVs adapt to diverse structural designs based on the distribution and connectivity of sensors and actuators. Commercial EVs typically employ large, high-voltage battery packs (600- 800V) with capacities ranging from 300-600 kWh, necessitating sophisticated BMS architectures. The most common types of BMS structures are as follows-

Figure 2: Block diagram of distributed architecture

The BMS is the nucleus of ESS performance, safety, and longevity in commercial electric vehicles. Its critical roles include:

For example, in electric buses with frequent charge-discharge cycles, BMS ensures safe fast charging, while in long-haul trucks, it optimizes energy efficiency for extended ranges.

Commercial transport ESS designs must balance energy density, power capability, and thermal management:

Recent advancements in BMS and ESS are significantly enhancing their applicability in commercial transport:

Modern BMS designs also enable high-power fast charging, significantly reducing vehicle downtime in commercial transport.

| Chemistry | Energy Density (Wh/kg) | Price ($/kWh) | Cycles | Safety |

|---|---|---|---|---|

| Li-NMC | 150–275 | 130–139 | 1500–5000 | Moderate |

| LFP | 80–150 | 70–105 | 3000–7000 | High |

| Sodium-ion | 140–160 | 80–120 | 4000–5000 | High |

Table 1: Comparison of Battery Chemistries for commercial EVs

| Transport segment | BMS focus areas | ESS requirements | Key performance |

|---|---|---|---|

| Urban delivery vans | Frequent start-stop cycles.Regenerative braking optimization.SOC accuracy in variable routes | 100-150 kWh capacity.High power density.Fast opportunity charging | Energy consumption: 0.8-1.2 kWh/km.150-200 km daily range.50-150 kW peak power |

| City transit buses | Predictable route profiles.High daily utilization (16-20 hrs).Passenger load variation | 250-350 kWh capacity. Pantograph charging. Redundant safety systems | Energy consumption: 1.2-1.8 kWh/km. Ultra-fast charging (450 kW). 10+ year service life |

| Medium duty truck | Mixed urban/highway cycles. Varying payload weights. Multi-shift operations | 200-400 kWh capacity. Flexible charging rates. Modular design | Energy consumption: 1.0-1.5 kWh/km. 200-300 km range. 200-250 kW peak power |

| Long-Haul trucks | Extended high-power output. Highway efficiency optimization. Long service intervals | 600-1000 kWh capacity. High energy density. Megawatt charging capability | Energy consumption: 1.5-2.2 kWh/km. 400-800 km range. 350-850 kW charging |

BMS and ESS technologies have emerged as the cornerstone of commercial transport electrification. These systems provide the essential intelligence and power management infrastructure driving this transition. Through advanced cell monitoring, multi-domain state estimation algorithms, and predictive analytics, these systems deliver the reliability and performance demanded by commercial applications. As the industry evolves, these technologies extend beyond vehicle management to enable vehicle-grid integration and support fleet-wide optimization. For engineers and operators navigating this transition, mastering BMS and ESS integration isn't just about technical excellence—it's about building the foundation for a sustainable transport ecosystem that meets tomorrow's operational, economic, and environmental imperatives.