A comprehensive guide to proximity sensors for industrial applications

In industrial and manufacturing settings, the swift and accurate detection of fast-moving objects is crucial for operational efficiency, productivity, and safety

A comprehensive guide to proximity sensors for industrial applications

In industrial and manufacturing settings, the swift and accurate detection of fast-moving objects is crucial for operational efficiency, productivity, and safety

Proximity sensors, such as ultrasonic sensors, capacitive sensors, magnetic sensors, optical sensors, and inductive sensors, play a vital role in identifying the presence or absence of objects in dynamic environments. This article explores types, principles, and techniques used in proximity sensors for industrial applications.

A proximity sensor uses a non-contact detection method to detect the presence or absence of an object. It operates based on various principles such as high-frequency oscillation type using electromagnetic induction, magnetic type using magnetism, electrostatic capacity type, and sensing changes in the electrostatic capacity between the sensing object and the sensor. This non-contact detection method ensures that the object remains undamaged. Proximity sensors are effective even if moisture or grease are present. These sensors provide high-speed response and are suitable for precise object positioning because of their high repeatability. Their high response frequency enables stable detection, even with fast-moving objects.

| Proximity sensor | Inductive proximity sensor | Capacitive proximity sensors | Optical proximity sensorsr | Magnetic proximity sensors | Ultrasonic Proximity sensor |

|---|---|---|---|---|---|

| Technology | Electromagnetic field | Electric field | Light (reflection or interruption) | Permanent magnet and reed switch | Sound waves (reflection) |

| Target Material | Metal only | Any material (metal, plastic, liquid) | Varies (reflective: any object, thru-beam: opaque object) | Ferrous metals only | Most materials (solids, liquids) |

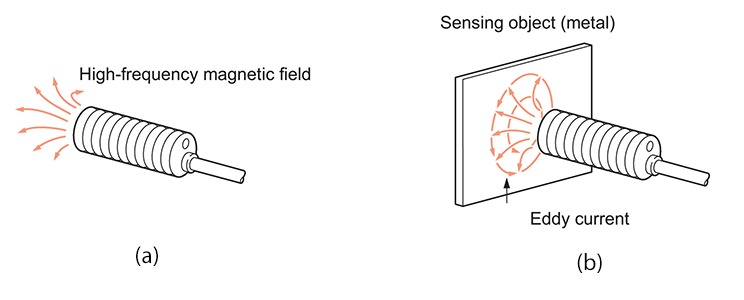

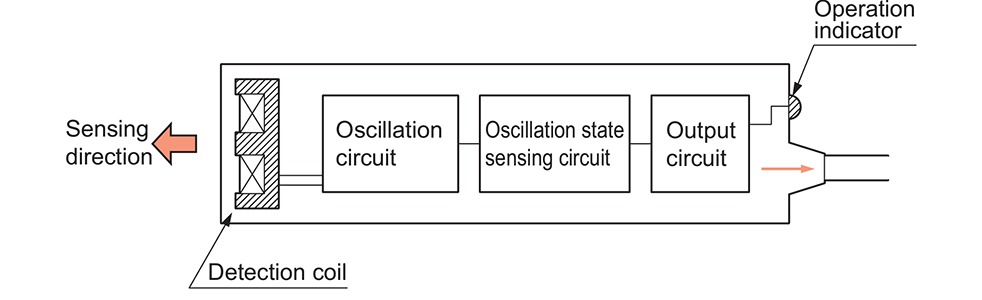

The sensor's oscillator generates a symmetrical, oscillating magnetic field that is radiated from the ferrite core and coil array near the sensing face, as shown in Figure 1. When target material that is ferrous in nature enters this magnetic field, small, independent electrical currents (eddy currents) are induced on the metal’s surface. Eddy currents incur thermal energy loss due to the metal's resistance, thus reducing the amplitude of oscillation. In Figure 2, detecting a change in the oscillation state prompts output operation.

Figure 1: (a) High-frequency magnetic field produced by the detection coil (b)The sensing object and detection coil interface produce an eddy current(Source)

Figure 2: Induction proximity sensor internal configuration(Source)

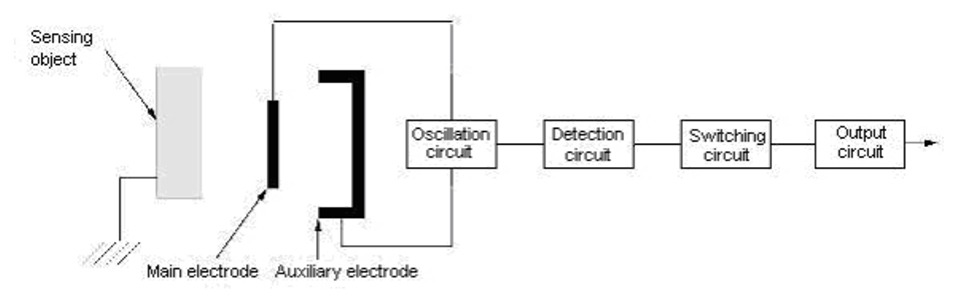

As the sensing element (metal or dielectric) approaches the electrode, the capacitance between the main electrode and ground potential increases due to the electrostatic induction effect. This change in capacitance triggers the CR oscillation circuit into motion. The approach of the sensing object is detected by observing the rise in the oscillation amplitude. For dielectric sensing objects, the variation in the capacitance between a central electrode and ground potential exceeds the large relative permittivity. The sensor detects this change. Figure 3 shows the circuit of the capacitance-based proximity sensor.

Figure 3: Capacitive proximity sensors internal configuration(Source)

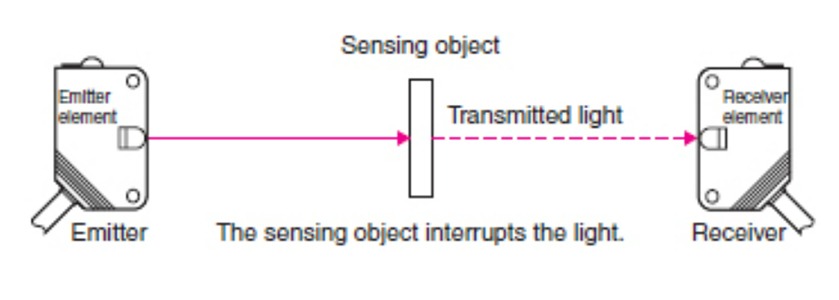

Optical proximity sensors detect changes in light intensity or interruptions of light beams to determine the presence or absence of an object within their sensing range or even the emission and reflection of light beams by the sensor. ToF and triangulation principles are popularly used in optical sensors for industrial applications.

The optical proximity sensors convert light emission signals into electrical signals. These sensors have a source and a detector. The response of the optical receiver varies according to the wavelength. Infrared light is the preferred light source due to its high intensity and susceptibility to interference.

Figure 4: Operating principle of optical proximity sensors (Source)

The limitations of optical proximity sensors are

Magnetic proximity sensors operate on several principles, such as,

Variable reluctance proximity sensors: These sensors measure the change in magnetic reluctance of a ferrous object in motion or at rest. They consist of a permanent magnet and a pickup coil.

Magneto-resistive proximity sensors: When an object with its magnetic field approaches the sensor, its electrical resistance changes. This feature helps detect the angle at which the external magnetic field (or object's position) is about the sensor.

Giant Magneto-Resistive Effect: In metallic layered systems, a significant shift in electrical resistance occurs when the magnetizations of the ferromagnetic layers are reoriented relative to one another under an external magnetic field. This phenomenon can be used to detect objects.

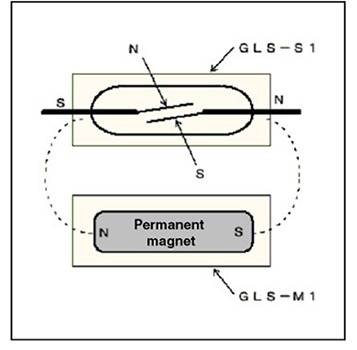

Reed switches consist of two ferromagnetic reeds (contact blades) that seal and are housed in a glass capsule. Magnets activate them.

Figure 5: Working principle of reed switches(Source)

Reed contacts that detect nearby objects using magnetic field distortion is shown in Figure 5. If a ferromagnetic material enters the sensor’s range, it changes the magnetic field, initiating a signal from the sensor.

The limitations of magnetic field sensors are:

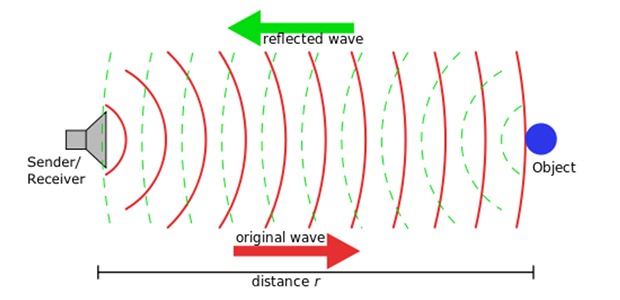

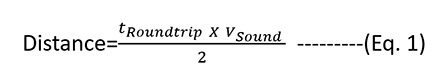

The principle of ultrasonic detection is based on measuring the time taken between transmission of an ultrasonic wave (pressure wave) and reception of its echo (return of transmitted wave), as shown in Figure 6. Eq. 1 gives the relation to find the range of the target.

Figure 6: The working principle of ultrasonic proximity sensors(Source)

From Equation 1 ultrasonic Distance Calculation can be obtained. Where troundtrip is the total time traveled, and Vsound is the sound velocity.

Ultrasonic sensors excel at detecting objects capable of reflecting acoustic waves, particularly objects having a flat surface perpendicular to the detection axis. However, the performance of the ultrasonic sensor can be impacted by:

Ensuring fast and dependable object detection at high speeds is critical across various industrial and manufacturing environments. Proximity sensors play a pivotal role in meeting this demand by providing real-time detection capabilities that enable efficient and safe operation of machinery and processes. Industrial professionals can optimize sensor selection by understanding the operational principles of proximity sensor technologies and considering factors such as sensor placement and environmental conditions to meet the specific requirements of their applications.

Farnell has partnered with many different suppliers catering to a wide range of Proximity sensors:

| Product | Key suppliers | Buy link |

|---|---|---|

| Capacitive proximity sensors | TURCK, OMRON, CARLO GAVAZZI | Buy now |

| Hall Effect proximity Sensors | LITTELFUSE, MULTICOMP PRO | Buy now |

| Inductive proximity sensors | TELEMECANIQUE SENSORS, MULTICOMP, PEPPERL+FUCHS | Buy now |

| Magnetoresistive Proximity Sensors | FESTO | Buy now |

| Miscellaneous Proximity Sensors | ELMDENE, OMRON, HONEYWELL | Buy now |

| Reed Proximity Sensors | STANDEXMEDER | Buy now |

| Ultrasonic Proximity sensors | TELEMECANIQUE SENSORS | Buy now |